stadiko

Leistungsstarke Reinigungstechnik, Wildkrautbekämpfung sowie professionelle Dienstleistungen.

Vom Reinigungs-Dienstleister in der Landwirtschaft, hat sich stadiko zu einem Hersteller entwickelt, dessen Reinigungstechnik in den verschiedensten Bereichen Anwendung findet.

Mittlerweile ist stadiko seit über 25 Jahren als innovativer Hersteller von maßgeschneiderter und professioneller Reinigungs- und Hygienetechnik bekannt.

Individualität, Langlebigkeit und Robustheit sind die Maßstäbe, nach denen wir handeln.

Weitere Informationen zu unserem Unternehmen finden Sie hier.

Full Service & Know-how

Neues bei stadiko

Messetermine

Tarmstedter Ausstellung

Datum: 12.07.2024 – 15.07.2024

Standort: Ausstellungsgelände Tarmstedt

Die stadiko Produktpalette für den Profi

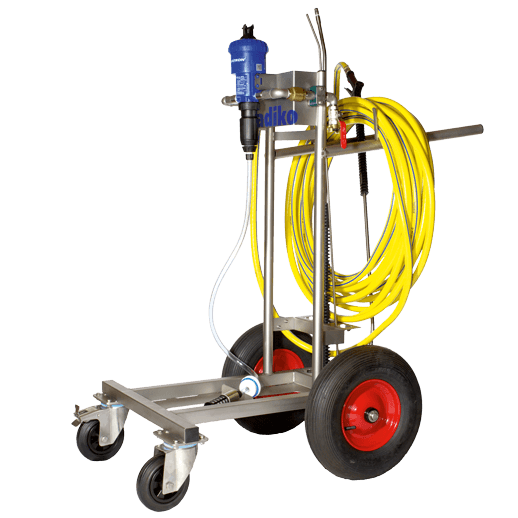

Mobile Hochdruckreiniger und stationäre Hochdruckanlagen werden stets maßgeschneidert auf die Bedürfnisse der Kunden angepasst. Bei stadiko erwirbt man nicht nur einen Hochdruckreiniger, sondern profitiert auch von der Kompetenz aus jahrelanger Erfahrung. Sie haben spezielle Wünsche oder Anforderungen? Nennen Sie das Problem und wir erarbeiten mit Ihnen zusammen eine Lösung.

Abgerundet wird das Angebot von stadiko mit einem neu entwickelten Gerät zur chemiefreien Wildkrautbekämpfung, dem „stadiko Ökotherm“. Mit diesem Gerät wird, konform mit dem aktuellen Pflanzenschutzgesetz, eine komplett autarke und chemiefreie Wildkrautbekämpfung mit Heißwasser möglich. Der gebrauchsmustergeschützte Ökotherm zeichnet sich durch seine Kompaktheit und seine flexiblen Einsatzmöglichkeiten aus, mit der auch kleinste Areale problemlos erreichbar sind.

Lernen Sie unser umfangreiches Produktangebot kennen!

Unsere Hygienedienstleistungen im Überblick

stadiko ist auch als qualifizierter Dienstleister im Bereich Hygiene tätig. In der Landwirtschaft übernehmen wir für Sie nach einer umfänglichen Bestandsaufnahme die Stallreinigung und Nassdesinfektion, die Siloreinigung oder Desinfektionen per Begasung - fachgerecht und kompetent.

Auch in weiteren Bereichen werden von stadiko Desinfektionsbegasungen mit langjähriger Erfahrung, modernstem Equipment und bestens geschultem Fachpersonal erledigt, wie z. B. in Schlachtereien und anderen Lebensmittel verarbeitenden Betrieben, Sicherheitslaboren oder Produktionsbereichen von Arzneimittelherstellern. Wir garantieren unseren Kunden eine sicherheits- und umweltkonforme, gründliche sowie nachhaltige Arbeit.

In punkto Schädlings- und Salmonellenbekämpfung wird stadiko von der Tochterfirma varEX GmbH nach der Devise unterstützt, dass eine richtige Vorbeugung besser ist, als einen Befall zu bekämpfen.

Mobile Hochdruckreiniger

Mobile Hochdruckreiniger Stationäre Hochdruckreiniger

Stationäre Hochdruckreiniger Zubehör für Hochdruckreiniger

Zubehör für Hochdruckreiniger Ökotherm

Ökotherm Ökotherm Zubehör

Ökotherm Zubehör Alzogur-Dispenser

Alzogur-Dispenser Sprüh- & Dosiergeräte

Sprüh- & Dosiergeräte Reinigungs- & Desinfektionsmittel

Reinigungs- & Desinfektionsmittel Containerbauweise

Containerbauweise Mitteldruckanlage

Mitteldruckanlage Frequenzgeregelt im Gehäuse

Frequenzgeregelt im Gehäuse Mehrstufige Hochdruckreinigungsanlage

Mehrstufige Hochdruckreinigungsanlage Waschkleidung

Waschkleidung Schutzmasken

Schutzmasken